We are pleased to introduce ourselves to manufacturers of various grades of POWDERED and GRANULAR activated carbon with trying to well-established name in the market through our consistent,Quality and timely supplies of activated carbon to various industries.

Read More

Introduction

Activated carbon can be made from a wide range of source materials such as coal,coconut shells and wood.The material is often charred to achive carbon,follow by activation by high temperature steam. This produces and activated carbon with an extensive network of pores and an extremaly high surface area (Typical Range is 300 to 1900 m2/g). The pores provide sites for the adsorption of chemical contaminants in gases or liquids.

Activation

Material such as a wood, coconut shells or coal that is activated bysteam is first carbonised to creat charcoal.The carbonisation is perform at a temperature at approximately 600 oC in an oxygen free atmospbhere. This process carry all of the organic compounds and leaves behind the carbon and minerals.

Steam Activation

The steam activation of the charcoal is that carried out an even high temperature up to 900oC In a steam atmosphere. The activation reaction between charcoal and steam can be described as follows:

C + H2o ———–> CO + H2

C + CO2 ———–> 2 CO

The activation process can be controlled to produce specific product characteristic. Steam concenstration,temperature,activation time and CO2 concentration influence pore development, which in term affect pore size distibutions and the level of activity.

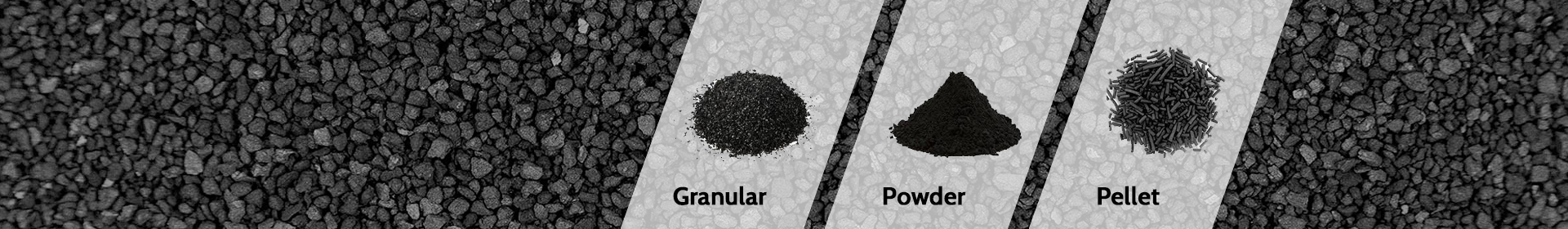

Forms of Activated Carbon

There are three main forms of activated carbon.

- Granular Activated Carbon (GAC)

- Powdered Activated Carbon (PAC)

- Pelletised / Extruded Activated Carbon

GAC - Granular Activated Carbon

The activated carbon is milled and sieved to achieve particles in the range of 0.2 to 5 mm. Typically the drinking water industry uses an 8 x 30 mesh (effective size of 0.80-1.0 mm), or a 12 x 40 mesh (effective size of 0.5 - 0.7 mm). GAC is used in both liquid and gas phase applications.

PAC - Powdered Activated Carbon

Powdered activated carbon is also milled and sieved and has a smaller particle size than the GAC. The PAC particles are mainly less than 0.18 mm (US Mesh 80) usually with a median diameter of 15 to 30 microns. PACs are generally used in liquid phase applications and for flue gas treatment.

Pelletised / Extruded Activated Carbon

The activated carbon has been extruded into cylindrical shaped pellets with diameters ranging from 0.8 to 5 mm. These are mainly used for gas phase applications because of their low pressure drop, high mechanical strength and low dust content.

Shocking Facts About Activated Carbon

Medical Treatment

Its porous texture binds to toxins and prevents your body from absorbing them. It draws out impurities. That’s one reason it’s a staple in hospital emergency rooms. Doctors commonly use it as an antidote for food poisoning and drug toxicity.

Kidney Diseases

For patients with end-stage renal disease, activated charcoal may be a viable alternative to dialysis. It binds to urea and other toxins, reducing the number of waste products that filter through your kidneys.

Gas and Indigestion

It helps to neutralize the liquids and gases trapped in the intestine and further ease pain, not required after gas. It has antiviral, anti bacterial, anti fungal and detoxifying properties which help in teeth whitening.

Skin Infections and Acne

Its anti bacterial, properties help it absorb harmful microbes from wounds. It might also help stop the smell that comes from infections and can help with ulcers or bedsores.

Cholesterol

Some research shows that activated charcoal can keep your body from absorbing cholesterol. It helps in dropping the LDL, or bad cholesterol.

Preventing Hangovers

Though it doesn’t seem to absorb alcohol very well, some research shows that drinking it at the same time as alcohol might lower blood alcohol levels somewhat.